The metal is also resistant to corrosion and so brass finds use in a variety of industrial applications. Brass CNC machining is a popular process for creating precisely layered parts and components from this malleable material.

CNC machining stands for Computer Numerical Control, in which a computer helps it perform cuttings and moldings precisely. Its strength and ease of handling make it one type of metal that works exceptionally well for CNC machining is the brass. This first process of the Brass CNC machining is the part or component configuration in a special software tool Computer-Aided Design (CAD) for their computerized representation. The design needs to be finalized first, and then the second step is programming a CNC machine in order for it can follow all those specifications from that created CAD file. Using a range of cutting tools, the brass material is then cut into shape and size through CNC machine with high precision & details.

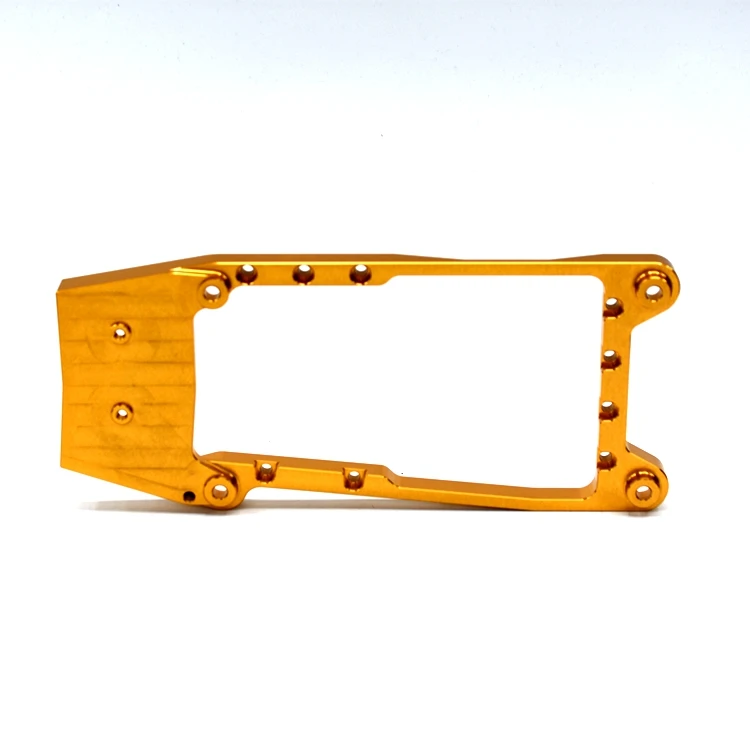

A skilled machinist with a specialization in Brass CNC machining focus on producing parts and components as precise and accurate as possible. They always use the best brass materials, as well cutting tools to make sure that what you get an excellent quality product in its class. Moreover, they try to bring down on the wastage and improve in machining process for better results.

Improvements in modern technology have made Brass CNC machining processes faster, more accurate and efficient. Contemporary CNC machines come with advanced computer systems to control the machining process, allowing machinists program a work and observe how it is executed in real-time-delivering precise results. Machinists use various cutting tools and methods to create detailed components, prototypes and high-quality objects.

Brass CNC machining can benefit manufacturers to optimize brass parts in terms of performance and value. For finishing, machinists have a broad range of techniques at their disposal to create either polished smooth or weathered finishes for their parts. In addition, they can add properties such as threads, holes and knurls to improve its using speed of the brass components.

To sum up, brass CNC machining is an accurate way to make high-quality parts and components with less material wastage. Use of cutting-edge technologies and well tested strategies by expert machinists ensure perfect results at all times as brass parts become stronger, perform better and also aesthetically superior for varied industry applications.

Yuyao Phelp Electric Appliance Co., Ltd., one of China's top three exporters of citrus juicers is leading the industry in terms of design and innovation and service quality. We are constantly striving to enhance our blenders and juicers by conducting research and brass cnc machining with new designs and higher quality to meet customer needs.

our range of products includes an array of high-precision parts for medical equipment as well as aerospace which includes parts used in heart stents we also offer durable and reliable parts for brass cnc machining we're committed to meeting these industries' needs in terms of material performance precision and innovation while ensuring that every item is manufactured to the most rigorous standards we fulfill the needs of our clients with top quality and cutting-edge technology

We have a complete quality management system that's accredited with ISO 9001 ISO 13485 ISO 14001 AS9100D and IATF 16949 It also comes with brass cnc machining for inspection and the services of a team of experienced quality inspectors Our quality assurance process encompasses each step of the process from raw material inspection to the final delivery of the product making sure that each product meets or even exceeds international standards and expectations We continually improve our production processes and train our employees regularly in quality management to improve our quality management standards

Our supply chain integrated seamlessly handles everything from basic material procurement to advanced processes such as brass cnc machining and titanium alloy oxidation This extensive approach combined with strict quality control ensures that each stage meets high standards delivering high-quality consistent and high-quality products and services that greatly improve customer satisfaction and help us establish our reputation as a trusted partner

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy