Do you ever stop and wonder how these everyday things that we use get made? A lot of the items which are more sophisticated than basic shapes by necessity must be made with intricate details covered in various complex parts. Brass Precision Components are one such types of parts that is used in salient number of objects for availing the unique features. But what are these parts, exactly - and how do they work?

Brass parts are small metal pieces composed of an alloy which is a mixture of copper and zinc. Due to their durability and corrosion-resistant properties, stainless steel wires are extensively employed in electronic gadgets, musical instruments as well as machine components. Brass precision manufacturing creates these parts for you.

Manufacturing needs to be precise in order for the final product to do what it is supposed todo. It is precision brass parts manufacturing, quality trends into consideration which may not withstand the functioning if these are not fitting together seamlessly with equal other components. Each step of the manufacturing process is subject to loss of precision which may lead to poorly fitting parts that can cause eventual product failures and breakage.

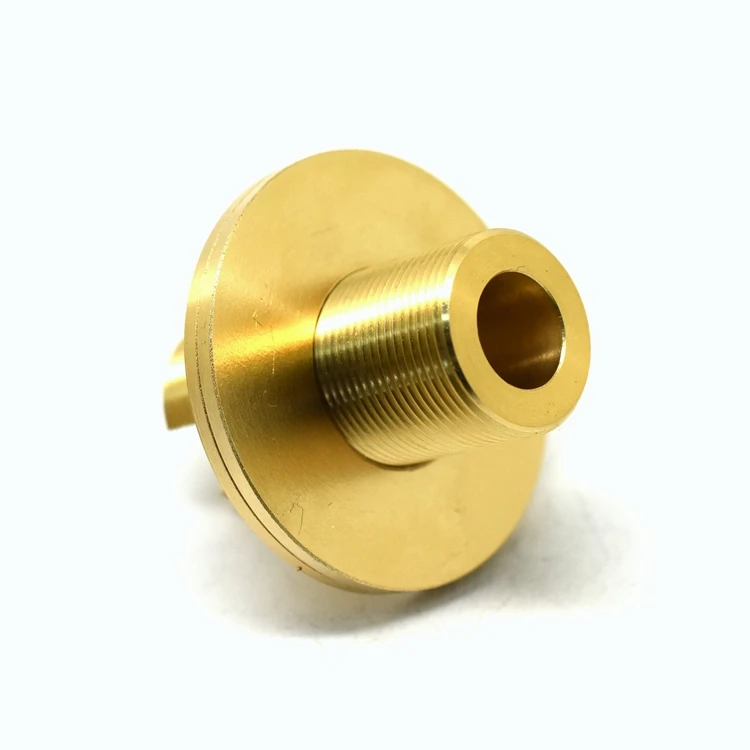

Said Brass precision manufacturing, consists of different important stages that form this path with each other. First, the brass is melted in order to be poured into a mold. The mold is a base of shaping the part, normally made from heat-resistant material such as steel.

Once the brass has hardened and cooled, it is pulled from the mold trimmed ever so carefully to remove all of that extra material. A part is then machined through a series of processes which involve cutting and forming it to the exact dimensions needed. It's also a very delicate process that must be carried out with the utmost care and precision, because any single slip could mean an entire part that needs to be thrown away.

An immerse part of brass precision manufacturing is machining, which involves the use of dedicated machinery to shape the brass into a desired configuration. It takes a great deal of skill and experience almost to the point that machinists working on these machines are by definition master craftsmen in their field. They also need to know how to read technical drawings in order for them ti understand what is needed of the task at that time.

These are materials that have high expansion and contraction rate, which expands the usefulness of brass precision parts across a wide range of industries including electronics, aerospace among others. The workhorse of modern life, these components are the invisible parts that still get things done.

our product line includes many high-precision pieces for medical equipment and aerospace such as components used in brass precision parts we also offer durable and reliable parts for industrial machinery we are committed to meeting the demands of these industries in terms of quality performance and technological innovation we ensure that all products are in line with the highest standards we fulfill the needs of our clients with top quality and cutting-edge technology

Our supply chain integrated seamlessly manages brass precision parts from the most basic materials procurement to sophisticated processes such as electroplating treatment of surfaces and titanium alloy oxidation The comprehensive approach and strict quality control ensure that each process is of the highest standards The result is efficient consistently high-quality reliable products and services that improve the satisfaction of our customers

Yuyao Phelp Electric Appliance Co., Ltd., one of China's top three citrus juicer exporters has led the industry in terms of innovation in design and quality of service. We constantly strive to brass precision parts our blender and juicer products, constantly researching and creating more innovative designs and superior quality to meet the demands of all customers.

We have a brass precision parts quality control system that's accredited with ISO 9001 ISO 13485 ISO 14001 AS9100D and IATF 16949 The system also comes with the latest tools for inspection as well as a professional team of quality inspectors From inspection of raw materials to the final delivery our quality control process ensures that each product meets or exceeds the international standards To improve our quality control standard we constantly improve our the production process We regularly train our employees on quality control

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy