CNC machining parts are some of the most crucial components used in various manufacturing industries. These components are very good, which is why they grow in demand and so many of the manufacturers prefer them. These parts have a large advantage in that they can produce things that really fit well together CNC Machining parts create far more precise and accurate shapes than older machines are capable of doing. When different pieces come together to create a larger product, they will fit seamlessly.

CNC machining parts are also ideal as they allow to produce different shapes and sizes from a given material. This versatility makes them suitable for just about any manufacturing requirement, regardless of the ergonomics inside a small or highly-automated large factory floor. It enables factories to create small parts for gadgets as well as large machine components. With this kind of flexibility, CNC machining parts have become a major component in the production process for many products that we use on a daily basis.

A CNC is a Computer Numerical Controller. So this means CNC machines are basically the metal cutting / metal forming equipment that is being controlled by sets of computer codes. CNC machining parts are produced using software that allows workers to digitally model the part on a computer. It gives them an idea of how the part will appear after being manufactured.

The worker then prepares the raw materials to be moulded into parts. They meticulously place it on the CNC machine. When every detail is set up, the CNC machine reads a computer code and starts to cut or process material in order to obtain desired shape. This software program "tells" the machine how to move/how things should be done so that in the end, everything is perfect and meets all of its required specifications.

Precision CNC machining is a process in which extremely accurate parts are made by the Compound NC machines. Which means they are all built to precise dimensions and specifications enabling each part (fitting) other parts perfectly in place. Such precision is critical in applications from aerospace and medicine-where even a small difference can make or break multi-million dollar systems-to automotive, where safety and reliability must never be compromised.

With the continued advancements of technology, CNC machining parts futures looks very promising. Now, factories are becoming populated with more advanced and smarter CNC machines that can repair themselves. This ability of self-correction means mistakes can be avoided more easily which leads to improved efficiency in the manufacturing process.

Even farther off into our current space future you can find the nature of CNC machining parts to become methods and materials that are even more foreign than they are now. I predict CNC machining parts will continue to be an integral part of the industry given that more and better precision and accuracy is continuously being demanded in all aspects regarding manufacturing. It contains: They will further evolve and adjust to random production conditions

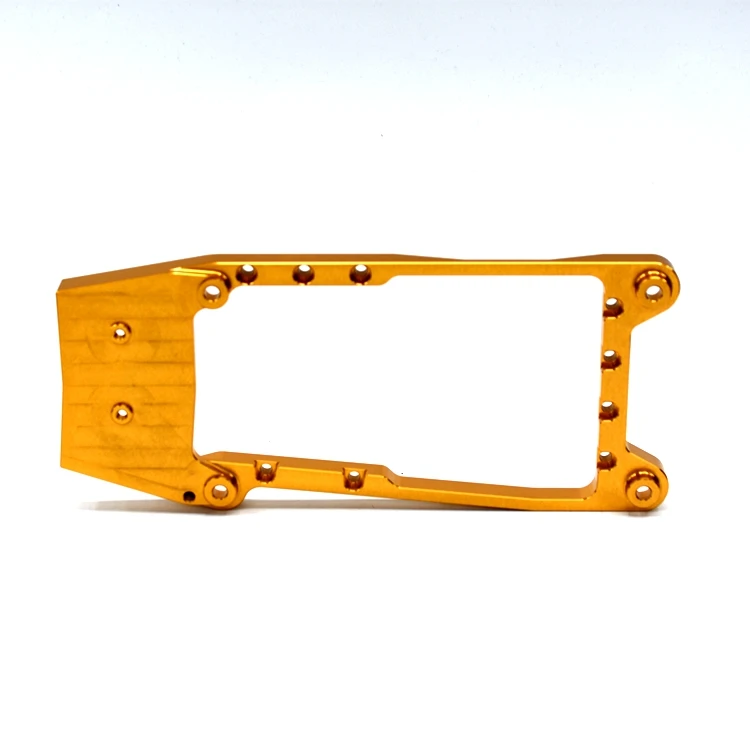

our product line covers many different cnc machining part components for the automotive as well as aerospace and medical equipment such as parts that are high-precision for heart stents and also durable and reliable parts for industrial machinery we're committed to meeting the needs of these industries for quality performance and technological advancement making sure that every product meets the most stringent standards we meet the needs of our customers by offering superior quality and cutting-edge technology

Yuyao Phelp Electric Appliance Co., Ltd., one of China's top three exporters of citrus juicers is leading the industry in terms of design and innovation and service quality. We are constantly striving to enhance our blenders and juicers by conducting research and cnc machining part with new designs and higher quality to meet customer needs.

Our supply chain integrated cnc machining part manages everything from basic material acquisition to more sophisticated processes like electroplating surface treatment and titanium alloy the oxidation process This broad approach coupled with a strict quality control system ensures that every step is in line with the highest standards providing consistently efficient and top-quality products and services that dramatically improve customer satisfaction and solidify our reputation as a reliable partner

We have a complete quality control system that's accredited with ISO 9001 ISO 13485 ISO 14001 cnc machining part and IATF 16949 It also comes with advanced tools for inspection as well as a team of professional quality inspectors Our quality assurance process encompasses every stage from the initial inspection of raw materials to final product delivery ensuring that every product is in line with or surpasses international standards and customers' expectations We continuously improve production processes and regularly train our employees in quality management to improve our quality management practices

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy