Welcome, learners! So, in that respect today we will talk about CNC machining parts. CNC stands for Computer Numerical Control and refers to a computer taking the helm of machinery in production tasks used parts.

One - a closer look at CNC machining This complex process takes advantage of computers order to control the way in which machines create parts out of raw materials. They make use of custom tools that shape the material into an exact form. CNC machines are so popular because they can be found in multiple different industries - from automotive and aero-space to medical device manufacturing.

CNC machining offers incredible benefits For this reason, one of the main advantages is to be able to produce parts with a level of precision and accuracy never seen before. This means the parts can be assembled tightly, which reduces waste and results in greater efficiency. Besides, CNC machines are also capable of producing more parts at a later rate and with greater consistency as opposed to traditional forms of manufacturing.

Advantages of CNC Machining for Industrial Parts

There are many gains to applying CNC machining for industrial parts. It allows for a degree of precision and accuracy that exceeds most traditional manufacturing methods. Besides, because they are computerized machines which do not rely on human full process involvement the production times and costs during fabrications can then be decreased as a sacrifice of rapidness& consistency. CNC machines are also able to machine a variety of materials from metals, plastics and composites adding versatility as well.

The limitations of the design have been revolutionized using CNC machining. CNC machines, unlike conventional mechanical methods which sometimes struggled to create intricate figures or geometries enable designers design parts of practically any shape or contour. This is achieved by using CAD/CAM software, which enables designers to configure the machines for different tasks. That new freedom has opened the door to more efficient and forward-thinking designs.

One of the key benefits from CNC machining with respect to manufacturers is being able to adhere successfully and effectively too industry standards and regulations. This compliance, particularly for industries such as aerospace and medical device manufacturing where part production must adhere to very specific regulations, is necessary. Using CNC machines, manufacturers can guarantee the fabrication of parts according to specific configurations which helps avoid expensive rework and product recalls.

Essentially, CNC machining is an integral part of a number industries. This enables increased accuracy, improved productivity and the generation of more complex designs than conventional manufacturing processes. Manufacturing in a way that abides by industry standards, produces economical parts and contributes to environmental sustainability has been made possible with computer-controlled machines. Therefore, the next time you see a custom industrial part think about how CNC machining probably had to offer assistance in its creation!

Yuyao Phelp Electric Appliance Co., Ltd, as one of the top three exporters of citrus juicers from China has always dominated the industry with design innovation and high-quality service. We are constantly striving to improve our juicers and cnc machining parts, researching and developing new designs and better quality to meet customer needs.

We have a cnc machining parts quality management system which is certified ISO 9001 ISO 13485 ISO 14001 AS9100D and IATF 16949 The system also comes with the latest quality inspection tools and a team of professional quality inspectors Our quality control system covers every stage from the inspection of raw materials through to final product delivery ensuring that every item meets or even surpasses international standards and customers' expectations To improve our quality management standard we continue to improve our the production process We also regularly train our employees on quality control

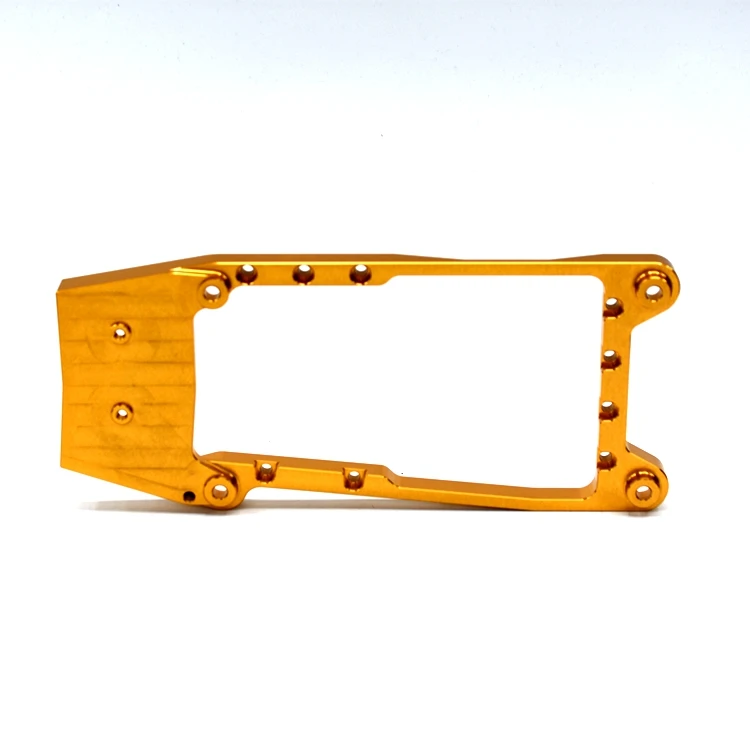

Our supply chain cnc machining parts seamlessly manages everything from the most basic materials procurement to sophisticated processes such as electroplating surface treatment and titanium alloy decomposition The comprehensive approach and strict quality control make sure that every stage meets the highest quality standards The result is efficient consistent and high-quality services and products that enhance customer satisfaction

our range of products includes an array of high-precision parts for medical equipment as well as aerospace which includes parts used in heart stents we also offer durable and reliable parts for cnc machining parts we're committed to meeting these industries' needs in terms of material performance precision and innovation while ensuring that every item is manufactured to the most rigorous standards we fulfill the needs of our clients with top quality and cutting-edge technology

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy