Did you ever wonder about how factories produce parts that fit one another perfectly well? It’s a fascinating process! These parts are made by factories using a unique process, precision CNC turning. CNC is computer numerical control. In other words, a computer assists in the operation of the part-forming machine. The material, such as a metal bar called the workpiece,will be rotated by CNC machine and cut in many ways to form according exact shape needed for every components.

The largest advantage of precision CNC turning is, it allows factories to produce very accurate parts. When we say that something is precise, it has been made in the correct way and without errors. This is especially critical as parts have to fit together accurately. For example, a CNC machine will enable workers to adjust the size and shape of material preciously before it is cut. That is why, each part made comes out identical which is what we really desired!

Very accurate cuts can be realised with the CNC machine, which are smaller than a small piece of paper! When parts need to sit right up against each other or have complicated shapes, this level of precision is very important. If a piece is not fabricated precisely then it might either not fit or function in general and that could lead to further complications.

Ok, but what if the part is a complex shape? And this is where precision CNC turning can be incredibly useful! This machine, with nearly as much dexterity and intelligence that its human counterparts once had (we assume? Having this flexibility is critical when working with irregularly shaped parts or that need to be assembled in a special order. For designers and engineers, it makes a lot more questions possible.

The trouble is, some of the most challenging parts to make are those with complex geometry that require several steps and processes. And yet all of these actions can be pre-programmed into the machine with precision CNC turning. This also means every part is fabricated in the same manner — a big advantage. This not only saves time, but it also saves money while ensuring all the parts are consistent and of good quality.

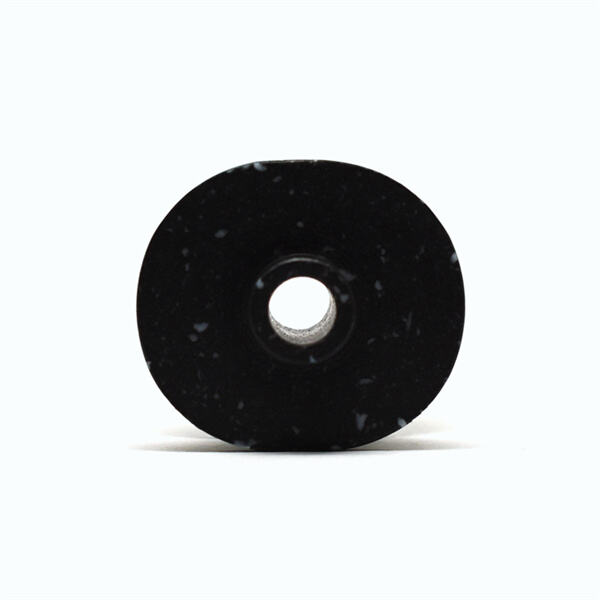

It is also great for parts that need fine detail, grooves or channels which it can machine during the CNC turning. Fitting details like these into a corner is an area where the CNC machine comes in handy to ensure that it will be cut with nothing less than perfect precision. It also has the ability to produce parts with intricate designs, such as engravings or text. All of these fine details can be extremely difficult to do by hand, but a CNC machine can handle the work quickly and with precision. This is especially critical for ornaments or decorative articles where aesthetic value plays a major role.

After all, precision CNC turning is critical in producing quality products. For factories, it helps them create parts that fit accurately and function correctly. It also saves time and money for factories. The machine processes quickly and precisely, thereby requiring less manual intervention from workers to do the job by hand which equals fewer mistakes on top of it. This leads to increased production times, cost-savings and therefore higher margins for the factories.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy