Stamped parts are key components in a wide range of factory __ manufacturing environments. Certain parts are made in specific manners so that they may be more robust and capable of a significant number of tasks. For stamping part manufacturer,man can consider several important elements that need to be known in order to generate high-quality products. However, they do need to understand the raw materials from which parts are made, thus enabling them to learn about manufacturing techniques and the type of machines that required for production. In order to retain a high standard on the parts, manufacturers would adopt multiple practices. These practices consist of practicing machine care through regular maintenance, looking for the best materials available and fit for its purpose as well as following strict guidelines to quality control — On which they check not only a sample but every piece according to standard.

In various industries and a variety of fields, manufacturers are always looking for new ways to stamping parts with more efficiency and faster methods. High-speed stamping machines are one of the most common methods they use. The speed of part production also remains a main priority and these machines are designed with capabilities to produce quick accurate parts. This enables manufacturers to produce many parts in less time whilst maintaining the quality. Beyond that, manufacturers often use custom software and high tech tooling technologies that help build complex parts with intricate shapes. Being able to provide this level of customization is critical for manufacturers so that they can cater precisely to the requirements and demands different customers have, which effectively guarantees unique parts fit perfectly with their intended use.

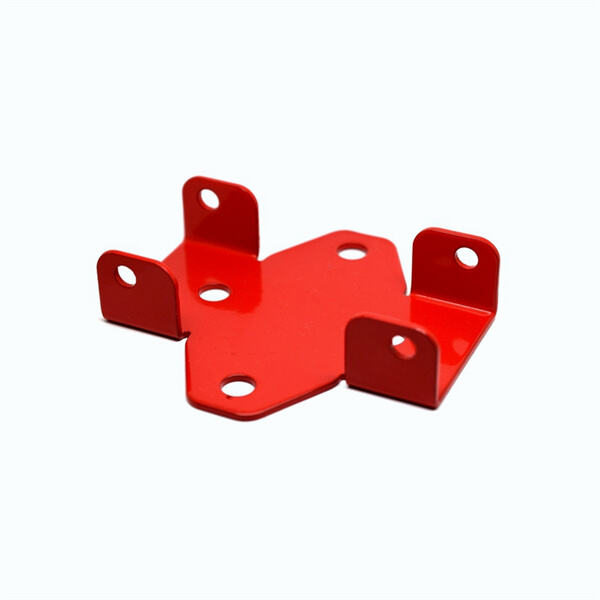

Stamping parts In different industries, stamping parts are very important in the modern world. For instance, the automotive stamping part is used in making several parts of engines, brackets body panels and many others. The parts can be used to manufactured products in the construction industry, such as roof tiles and structural components. In health sector also, stamping parts are used in preparing surgical tools, dental implants and many more such devices that could be considered quite useful for the medical fraternity. Since the application range of stamping parts is so wide, its efficiency and important in modern factory operations can be imagined. Without these components, most everyday use products will not work either.

One the biggest issue that every business has is what are they required from their products. These needs will involve the development of special stamping parts that are created just for them. Manufacturers need the right tools and manpower, providing us with custom parts. Manufacturers must collaborate together with their customers to design the parts and get them meeting all required criteria. Custom stamp part manufacturing is a multi-step and often iterative process to meet the specific needs of any given customer. This collaborative method further solidifies the relationship between manufacturers and customers.

Stamping parts have a wide range of uses, which can be applied in many fields imaginable. They are instrumental in the manufacture of an array of products from toys to household items, electronics and planes.We have a long list! Stamping manufacturers strive to fit the sheet metal stampings produced by them with every industry they serve. The leveraged the same experience and technology to create ejunction stamping parts which are not only strong, durable but also has great mechanical properties. Their widespread use in the production field is because stamping parts deliver versatility and can be fitting to different applications/tasks.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy