Бъдещето на правенето на неща: Продукти от CNC фрезеруване

Давно, много преди времето на технологиите, хората прекарваха часове, работейки с ръце и инструменти, за да произведат обекти. Но развитието на технологиите намали този вид дейност до голяма степен. Помощните видове са налице в големи числа. Все по-сophisticirani CNC обработени продукти са в авангарда на съвременното производство.

Това е скъсяване на израза Computer Numerical Control - това означава, че предметът, който се прави (в този случай елемент от дрехите) има компютърна система, която надгледа как и кога да се направи в една машина. Има много предимства при използването на продукти, обработени чрез CNC. Те предлагат по-висок ниво на точност, например по-висока от ръчноизработените продукти. Тази безкомпромисна точност се достига поради това, че компютърът прави 100% точни измервания и работи много по-бързо отколкото хората биха могли да го направят. Освен това, съществува последователност при частите обработени чрез CNC до n-та степен, което означава, че всяка част izглежда абсолютно идентична. Специално важността на еднородността е най-висока в индустриите, които изискват висока прецизност.

Фрезерната обработка с ЧПУ е вид автоматизация (която завършва с последния ми блог за иновациите), която включва използването на машини за контрол и манипулиране на програмирането на задачите, които преди това извършваха хора. Този преход към автоматизирана работа има различни предимства, като например подобряване на продуктивността и намаляване на разходите. Един компютър може да контролира няколко машина едновременно чрез фрезерната обработка с ЧПУ, което позволява по-бързи производствени процеси с по-малко отпадъци.

Разберете процеса на фрезерната обработка с ЧПУ

През проектирането на процеса за CNC обработка се включват няколко критични стъпки. Първоначално проектът се създава чрез компютър, след това този проект се изпраща към CNC машината, която го четe и генерира програмата, която й разказва как трябва да работи. Машината после използва своя инструменти за да рязне, пробива или формира продукта според начинът, по който е бил проектиран. След като тези стъпки са завършени, продукта се проверява, за да се определи дали отговаря на определени спецификации - Този процес може да се повтаря безкрайно много пъти, за да се получат множество идентични предмети.

Създаването на най-добрия продукт, обработен чрез CNC, изисква комбинация от умения и знания. Една от процедурите, които е важно да разбере дизайнерът, който проектира такъв продукт и извежда всяка фаза в разбираем формат за CNC машина. Освен това трябва напълно да разберете материалите, които се използват, тъй като различните настройки на материалите изискват други настройки на машината. Операторът на CNC машина също ще гарантира, че е достатъчно умел за внимателното изпълнение на функциите си, докато разглежда причините за възможните проблеми, които могат да възникнат по време на производството.

Изработените на чекмедие продукти се използват в голямо разнообразие от индустрии, включително аерокосмическа, медицинска и автомобилна, докато деталите обработени чрез CNC отговарят на нуждите в различни производствени индустрии. Аерокосмическата индустрия е развила масивно чрез употребата на продукти, обработени чрез CNC, за създаване на компоненти за самолети и космически апарати. Също така в медицинската област, където тези предмети се използват за правене на имплантати и протези. Компонентите, обработени чрез CNC, играят ключова роля при производството на автозапчастни, особено в автомобилния сектор (функции) (например Cranfield). Всичко пак, CNC обработка не е само за промишлено използване. Благодарение на компании като Pinshape, потребителите могат да получават и предмети, които се извиксват над простите ювелирни изделия и чехли за телефoni - например персонализирани играчки, произведени чрез методите на CNC обработка.

Така че, да си направим резюме - продуктите обработени чрез CNC са бъдещето на производството. При сравнение с традиционните ръчно изработени продукти, при заседения всички техни характеристики предлагат не само по-висока точност и последователност, но и процесна ефективност, която може да бъде недостъпна при ръчното коригиране. С увеличаването на популярността на CNC обработката за всички видове индустрии глобално, като автоматизиран процес, CNC обработката е доста сложна процедура; следователно, за да се произвеждат висококачествени продукти, машинистът трябва да е експерт в тази област, тъй като с професионални техники това има много потенциал и сила да дава добри резултати. Бъдучи складуване най-важно за промишленото използване, на друг ниво - обслужване на портфейли; продуктите обработени чрез CNC преобразуват бизнес сценарии.

Yuyao Phelp Electric Appliance Co., Ltd, като една от трите най-големи експортёра на цитрусови соковици от Китай, винаги е доминирала в индустрията с иновативен дизайн и висококачествено обслужване. Ние постоянно се стремим да подобряваме нашите соковици и продукти, обработени чрез CNC, разработвайки нови дизайни и по-добро качество, за да отговаряме на нуждите на клиентите.

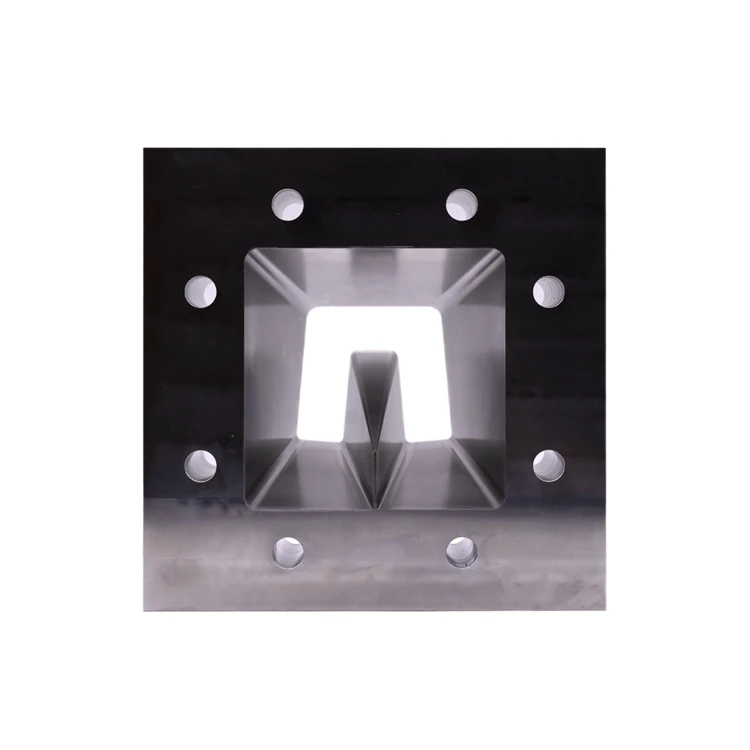

нашата линия продукти покрива много различни продукти, обработени чрез CNC, включително компоненти за автомобилната промишленост, както и за авиационната и космическата и медицинското оборудване, като части с висока точност за хъртови стентове, както и издръжливи и надеждни части за индустриална машинария. Всички продукти отговарят на строгите стандарти. Ние сме ангажирани да отговаряме на нуждите на тези индустрии за качество, производителност и технологично развитие, гарантирайки, че всеки продукт отговаря на най-строгите стандарти. Предлагаме превъзходно качество и резервни технологии.

Нашата логистическа верига е интегрирана и безпроблемно покрива всичко от закупуването на основни материали до напреднали процеси като електрохимично засичане, обработка на повърхността и продукти, обработени чрез CNC. Комплексният подход и строгият контрол върху качеството гарантират, че всяка фаза е според високите стандартни норми. Това води до ефективни, постоянно висококачествени, надеждни продукти и услуги, които подобряват удовлетвореността на нашите клиенти.

Относно контрола на качеството ние сме създали ефективна система за управление, призната от ISO 9001, ISO 13485, продукти обработени чрез CNC, AS9100D и IATF 16949. Обектът е оборудван с модерни инспекционни инструменти и екипирани с изкуствен Екип за Контрол на Качеството. От първоначалната проверка на суровите материали до крайната доставка на продукта, нашата система за контрол на качеството гарантира, че всеки продукт отговаря или надхвърля международните стандарти. За да подобряваме стандартите на управлението си по качество, постоянно подобряваме производствените процеси. Редовно обучаваме нашите служители в областта на управлението на качеството.

Всички права запазени за Huizhou Jiyan Hardware Co., Ltd | Политика за поверителност