Your browser does not support the video tag How many times do you think about how the things around us come from? Machines play a major part in the making operation of anything from your favorite toy to those cars which pass you on roads. From these machines, one of the machine is called CNC Mill which plays a significant role in making things. Most of the items we use on a daily basis would not take so less time to create without CNC Mills.

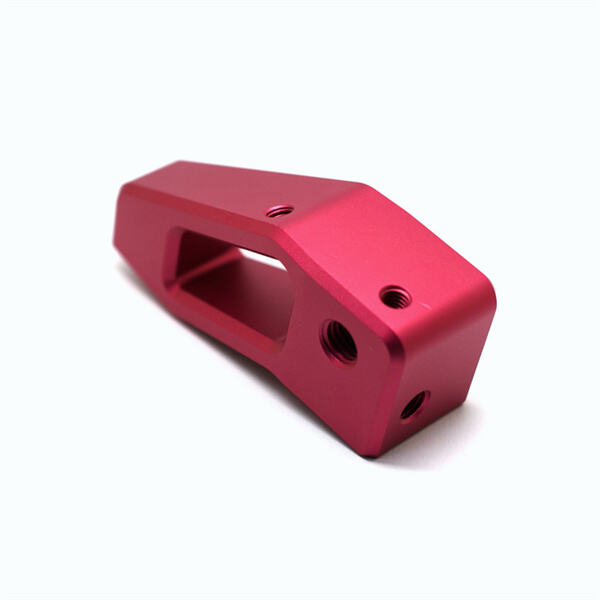

A CNC Mill is a machine that cuts and shapes materials using cutting tools, most often drills. CNC Mills, on the other hand are awesome because they require a computer. This means they can literally make surgical cuts and shapes. A CNC Mill is used to produce more accurate parts than can be done by hand. This is what allows for such precision — but in doing so, it also gives reason as to why CNC Mills are a godsend when you work on bulk manufacturing projects.

Prior to the availability of CNC Mill Machining, creating parts was a lengthy and arduous process. Workers would not cut and shape parts by hand or less precise machines. There may be many of them and it could take awhile, making mistakes likely. CNC Mill Machining on the other hand reduces such mistakes thereby making parts faster. This is perfect integration of parts using the accurate machines is greatly required to form Високо качество Products.

CNC Mill Machining also rapid efficient. The machines are able to work continuously throughout the day and night, producing parts without any rest periods. As a result, they can switch tasks easily without the machines needing to stop and be re-parameterised for new jobs. This task switching capability is so much more efficient that it saves a lot of time, money & resources which ultimately makes the production huge cost effective.

Using CNC Mill Machining can also mean a savings for your business. Thanks to the flexibility with which they can be set and then proceed, these machines are quickly able to make parts without excessive labor costs. Newer machines also break down less and as a result require lower maintenance costs. And you save even more money in the long run with less production mistakes (no wasting of materials and time).

If your business is manufacturing parts or products, you will be off hiring the CNC Mill Machining. Since these machines are faster and more accurate, you can actually make a higher volume of parts in less time without as many errors. This means that growth decelerates and it is harder to scale a business because you are out of touch with what your customers want from you.

You can also develop innovative and new products using CNC Mill Machining as well. The machines' accuracy also allows you to build more detailed parts, which were difficult or impossible before. This clears up the way for innovation to develop new products of yours or enhance one respectively. These machines can even work with a wide range of materials, meaning you have the opportunity to diversify your product line.

Авторско право © Huizhou Jiyan Hardware Co., Ltd. Всички права запазени | Политика за Поверителност