В резултат на това, неръжавеящата оцел CNC се използва за изрязване на инготи от витка, както и за превръщането им в поръчвани по желание модели манекени и количества. Това е още по-критично, тъй като се използва за производство на голямо разнообразие от продукти. Това може да включва части за самолети, автокаросери и компоненти за медицинско оборудване сред другото. При работа с неръжавеща оцел, CNC обработката предлага редица предимства. Те могат да бъдат по-точни, изработени от много по-твърди материали и да реплицират много по-голяма сложност от част, която би отела месеци, но с декселността на човешките ръце.

Неръжавеящата оцел е популярен материал за метална фабрикация, тъй като този тежкият материал предлага висока сила и качество, а също така позволява нещата да бъдат направени според техния визаж, който ще продължи винаги. Това прави материалът устойчив при износ, поради което утюжката няма да изисква честни корекции, за да се поддържа. Освен това, нещо специфично за неръжавеящата оцел е, че тя никога няма да ржавее. Това я прави идеална за продукти, устойчиви на вода или за твърде жестоки среди (например: кухни, навън под дъжд и т.н.).

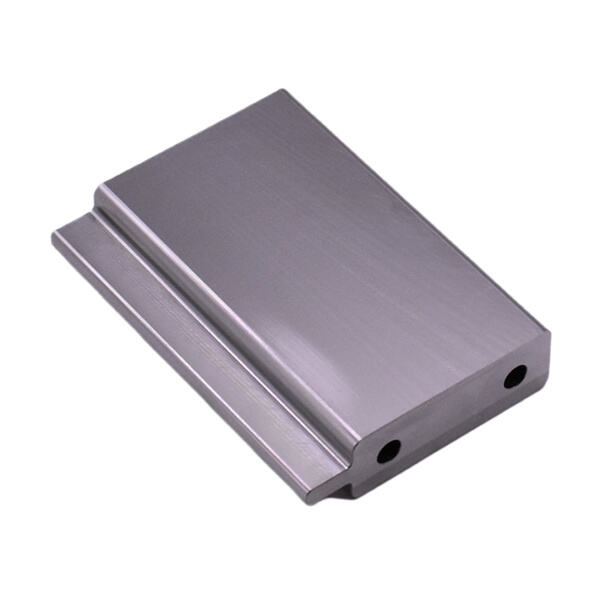

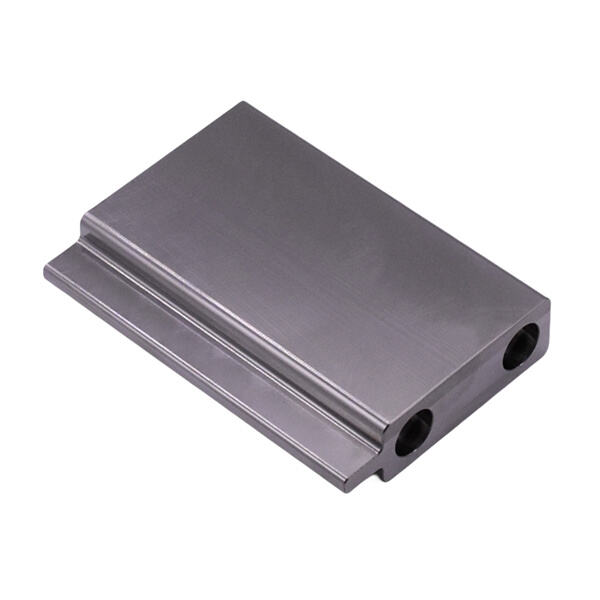

Тези изображения или модели на неща, които ни харесва да правим, се импортират в специален ( ) софтуер за камърна ос, и после се манипулират чрез специализирани компютърни програми, за да се получи 3D изображение, както е показано по-долу. Тези изображения предоставят на машините конкретни познания за това как да отпечатат тези части правилно. То се представя с равен размер и форма, чрез подобрено изображение, така че отново и отново могат да се произвеждат идентични продукти от неръжавееща стомана. Е, млади мъже и дами, това е нивото на съгласуваност, което води всичко лесно да работи заедно в хармония.

Някои от най-често използваните процеси при обработка на неръжавеща оцета с CNC: Токарене, Бурене, Фрезиране. Фрезирането е процес, при който материалът е закрепен в машината и тя автоматично фрезира, брише или извади определени части, за да се получи необходимата форма. Буренето на дупки обикновено е по-практично, когато металните изделия трябва да бъдат произведени само с използването на дупка. Ротацията се използва при производството на закръглени детайли или цилиндрични продукти. Всичко това обаче е малка част от това, на което са способни CNC машините. Това прави работа с сложни форми много лесна и изисква почти никакви усилия.

Много пластична Неръжавееща оцел е един от най-лесните материали за обработка и предлага някои специфични предимства спрямо другите видове. Материалът може да се справи със здраве - много от него, което означава, че без да се деформира или променя формата, той често стои по-добре от другите при интензивно физическо напрежение. Той е също така устойчив към висока температура и корозия, давайки възможност за производство на различни прочни части на продукта. Неръжавеещата оцел е също относително лесна за поддръжка, така че средният домакин трябва да получи много години използване преди да има нужда от замяна. Като индикатор за дълговечност, производителите предпочитат да я използват, защото те също така тестват продуктите си, за да бъдат функционирани, като се има предвид, че хlorine dioxide (хлорен диоксид) е наличен.

Подобно на това, технологията е относително важна в CNC обработка на неръжавеяващо цинк. Сега те могат да програмират компютри за чертане на сложни 3D модели на продукти за производство. Тези модели могат да се използват за предаване на компютърните машини, които след това ще конструират обектите според разработените алгоритми. Всяка CNC машина може да извършва множество задачи едновременно. Това им позволява да създават сложни дизайни и форми бързо. Всички тези технологични напредъци са довели до подобряване на скоростта и процеса на производство по-евтини, ползи, които организации могат да предадат на клиентите.

Всички права запазени за Huizhou Jiyan Hardware Co., Ltd | Политика за поверителност