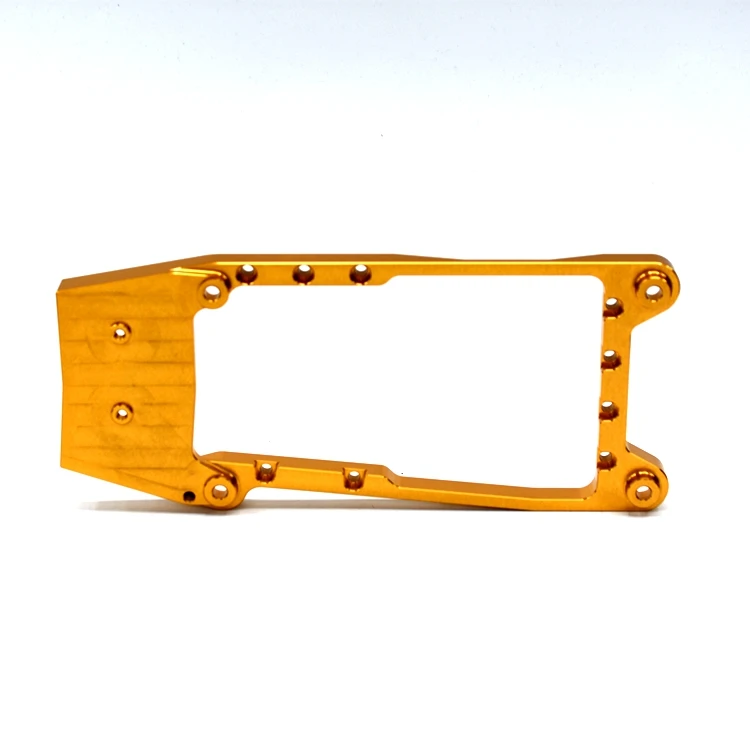

Metal that is bent with any sort of shape or curve through it. It would probably have been built with a milling machine, which is very much like this: Milling is a method used to fabricate parts by using high-speed tools spinning with sharp cutting edges to cut and shave material from solid blocks or rods. This multi step process continues to take away objects in order for what remains fits the final model perfectly! You can find these parts in everyday objects ranging from toys to cars.

Milling is not limited to metal cutting in industry, because many of the elements and objects we see around us (and use every day) are produced with milling remnants - plastics, ceramics or any other types of synthetic materials. It can build parts of wood, metal as well as plastic etc. The design of the part is a good start for milling. This design clearly defines how the part should turn out. When as the design is submitted, this then becomes a program. This program instructs the milling machine so that it cuts away material to give us our part. We replicate the design so closely that it fits perfectly in whatever we are using it for.

They are not all the same however, some milling machines differ from other to varying degrees. Each type of it has its own relevance and significance. Some machines are very fast for making large parts, some can only do detailed small things quickly. If you understand the part that is being made, then better to choose these machines for milling. A machine that you might use if making large parts then this will be different from a smaller intricate part.

When you are milling parts, high level of precision is essential. This error';s even if these tiny errors really matter and make your part unusable at the end. To be more exact, you first need to decide on the cutting tools. These tools need to be right for the material you are working with. And equally important would be proper care of the milling machine. The machine is then functioning at the highest level it can, this way the regular maintenance causes that. Last but not least you need to use correct techniques when you are using the machine By doing it right the steps will ensure your parts are to spec and within tolerance.

Milling involves using a variety of tools to get different jobs done. The most standard tools consist of End Mills (used primarily for cutting flat surfaces), Ball end mills (for creating rounded or contoured finishes, and fly cutters used to create smooth flat surface. All types of tools are meant for specific operations and choosing the right one could significantly increase the part quality in the end.

But even experienced machinists can have trouble milling parts. Common issues like tools breaking or the machine making odd noises, not everything ending up correct size-wise. It can also halt the process if a tool breaks, causing delays. Worse, these unusual noises could indicate that the appliance has a problem to address. Incorrect sized parts can cause wastage of time and materials. Before we get into that, let us know what causes these issues and how they can be solved. Your knowledge of the source can give you a clue as to how best approach fixing it and going back to work.

Our supply chain integrated seamlessly milling parts everything from basic material procurement to advanced processes such as electroplating surface treatment and titanium alloy oxidation This broad approach coupled with a strict quality control system ensures that each stage is in line with the highest standards providing consistently efficient and top-quality products and services that dramatically improve customer satisfaction and strengthen our reputation as a reliable supplier

our milling parts includes many different precision components for the automotive industry aerospace industry and medical equipment such as high-precision heart stents made of metal and also durable and reliable parts for industrial machinery we are dedicated to fulfilling the specific requirements of these industries for quality performance and innovation ensuring the quality of each item meets the highest standards we satisfy the demands of our clients by providing superior quality and innovative technology

We have a complete quality management system that's accredited with ISO 9001 ISO 13485 ISO 14001 AS9100D and IATF 16949 It also comes with milling parts for inspection and the services of a team of experienced quality inspectors Our quality assurance process encompasses each step of the process from raw material inspection to the final delivery of the product making sure that each product meets or even exceeds international standards and expectations We continually improve our production processes and train our employees regularly in quality management to improve our quality management standards

Yuyao Phelp Electric Appliance Co., Ltd., one of China's top three exporters of milling parts has led the industry in terms of design and innovation and service quality. We continue to enhance our blender and juicer products, constantly researching and creating new designs and higher quality products to meet all customer requirements.

Autoriõigus © Huizhou Jiyan Hardware Co., Ltd. Kõik õigused kaitstud | Privaatsus