That's right, they would be richer than that kid above for sure if I knew.... Making parts of machinery what makes machines and cars move... we should not forget this is needed work. Slightly boring for parents working in the sectors listed above, perhaps... but not kids! When we say manufacturing parts, it means taking a raw material like metal and plastic then cutting in a special manner that results the forming of custom part. The machining is a process to manufacture these parts, where Milling consist in the way of sculpt materials by using a spinning tool that removes pieces from material and achieves this piece.

How does CNC machining work? What this means is that we are making our cuts very accurate, I call precision cuts and it's really important to have these for you can make good parts. CNC machine can produce parts for a large selection of fields, and include airplanes to medical tools or mechanical pencil drums. CNC machining makes way for exquisitely crafted parts, a feat so complex that it would be impossible to achieve by hand.

There are, however a couple of little things that need to be whipped up and do have quite detailed fitment so they go exactly where the manual says or not at all. Well, by complex parts we mean those that have multiple features and can be produced with great difficulty. It also indicates the detail and quality required to ensure that individual components are produced absolutely perfectly because of course, if they were made a fraction larger or smaller than was intended, then would not fit together. This is one of the main reasons that machining continues to be a necessary step in creating such components.

Machinists are the people that run these machines, and they use several methods to create detailed components. Wire EDM - Some people use of Electrical Discharge Machining. The piece is then cut with electricity, hence the detail we can get. Now, for those tight tolerances you need to be able not only read precisely but make minute migrations as the milling is going on The higher level that you build something detail and the better its parts are integrated, they will fulfilling their role correctly for longer amounts of time more reliably.

It combine tools like grinding, polishing and honing which are used together to mechanically produce a perfect surface. These processes help to make the bump for any harsh areas on this section of cutter. A smoother, flatter surface may in some cases allow the part to perform at its best. This indicates the part will certainly execute above much better as well as much longer, that make it extra efficient at whatever task you need done.

Machining is a key element of the production process for components in numerous jobs throughout different sectors including aerospace, automotive and also medical tools. Such firms require quality parts that are sturdy and precise. Lastly, and more importantly to some: racing components are generally carefully designed and manufactured because they have to not only perform if mandated but often also need them too- in many cases mandated benchmarks on safety-so as reliably as fundamentally possible.

For example, the materials that will be used in aeroplanes should not only strong enough so they can endure throughput conditions such as extreme temperature and pressure change but also light in weight. For medical devices the components must have exacting specifications - being off by even a hair could destroy lives and pry loose millions in litigation dollars over parts that tiny mistakes would blanket. Car parts, in other words: the type of components found most everywhere on roadways - have to be durable and dependable for those passengers that count. Because these are critical applications, parts must be machined to exacting tolerances to ensure everything functions as it should.

Yuyao Phelp Electric Appliance Co., Ltd which is one of the top three exporters of the citrus juicer in China is always leading in the market with its machining part and top-quality service. We are always striving to improve our blender and juicer products by constantly analyzing and developing more novel designs, and more durable products that satisfy the needs of our customers.

For quality control we have established a comprehensive management system certified by machining part ISO 13485 ISO 14001 AS9100D and IATF 16949 We are also equipped with sophisticated inspection tools as well as an experienced quality inspection team Our quality control process covers each step of the process from the inspection of raw materials through to the moment of delivery of the final product and ensures that every product is in line with or even surpasses international standards and customers' expectations Continuously improve the production process and train our employees regularly in quality management in order to raise our quality management practices

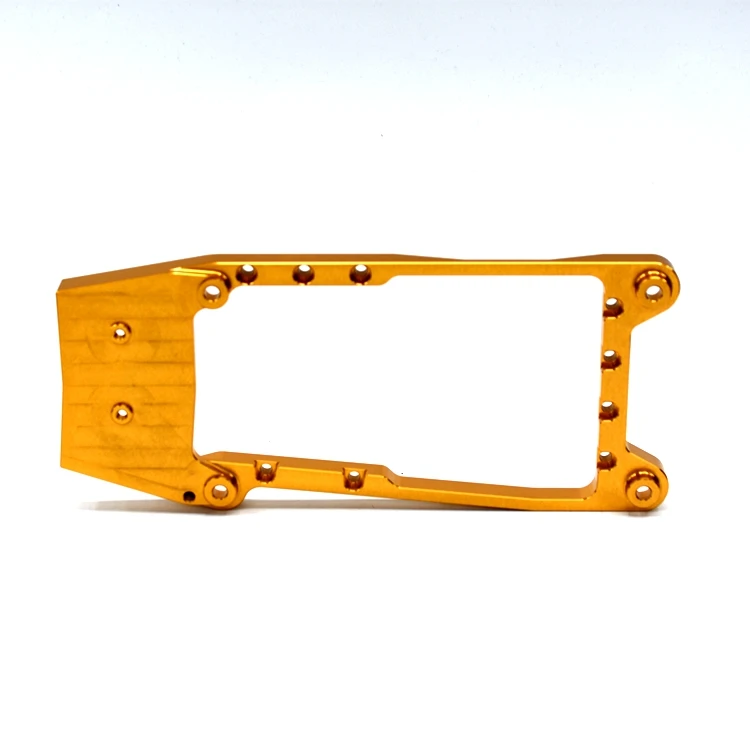

our machining part includes many different precision components for the automotive industry aerospace industry and medical equipment such as high-precision heart stents made of metal and also durable and reliable parts for industrial machinery we are dedicated to fulfilling the specific requirements of these industries for quality performance and innovation ensuring the quality of each item meets the highest standards we satisfy the demands of our clients by providing superior quality and innovative technology

Our supply chain integrated seamlessly manages machining part from the most basic materials procurement to sophisticated processes such as electroplating treatment of surfaces and titanium alloy oxidation The comprehensive approach and strict quality control ensure that each process is of the highest standards The result is efficient consistently high-quality reliable products and services that improve the satisfaction of our customers

Copyright © Huizhou Jiyan Hardware Co., Ltd. Alle rechten voorbehouden | Privacybeleid