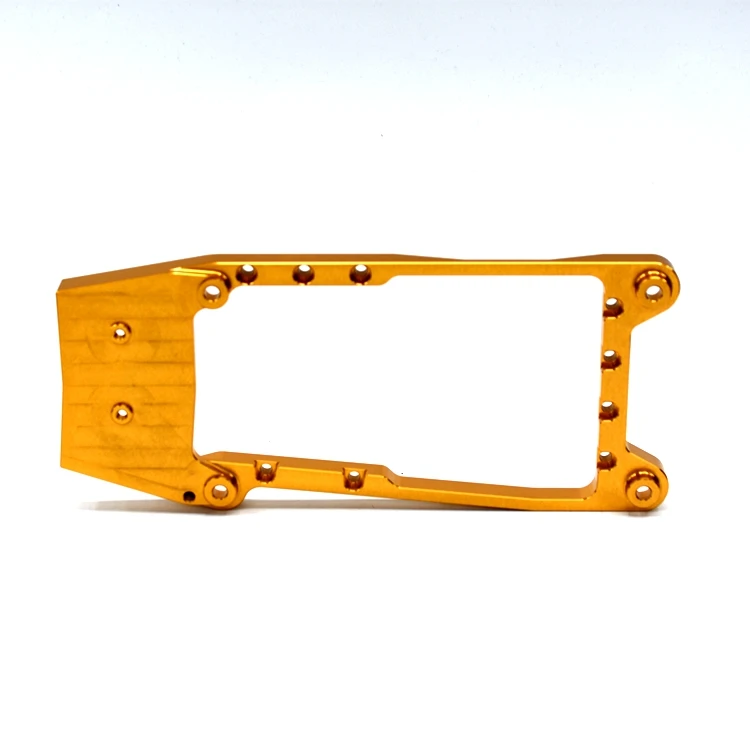

If your job is to manufacture toys, tools or any device always make sure that the parts produced are of correct size and perfect shape as it has a significant impact on daily life. This can go a long way, considering the fact that if they are not 1:12 or even worse ( as was in this case) off by just an inch on all four sides of its frame then none will be able to interlock with others and it would sometimes fall apart altogether. Apart from this, CNC machinery is a sophisticated and modern way of manufacturing parts. In this process a computer is used to control and drive the materials cutting and forming. Our technology can produce parts as thin as hair, with detail that is extreme and consistent in every case.

Imagine you are going to make a toy car. Needle-less to say, this includes some all-important elements - wheels and axels minimum; may be a shell as well for the body and little sprinkles here and there that makes it look real (Like headlights!) If any of these parts are replaced by poorly manufactured ones then the car will not work as it was supposed to. Like, if the wheels are too big they would not be able to stay on top of the axles in design space as well as for good rolling. It is also a simpler way of making sure CNC machining if all parts are properly done. You can tell the computer exactly how many centimeters you want each wheel, axel and compenent to be. The machine will take care of that and voila! You sit it just right.

However, CNC machining is not only remarkably accurate but also impressively quick. This means that you can produce parts quickly and repeatably, exactly the same way every time. This is a big advantage! Previous part-making methods were slow, and had a great deal of variability-one-off built in to the operation-whereas CNC machining was well known for treating all parts identically on every production run. This in turn saves time, and thus money - which is great for businesses that need to mass produce many parts.

In order to have the parts made by way of CNC machining, a person will need certainly an outstanding company who is able to perform functions competent. WHY DO YOU WANT TO EXPERIENCE THE MANUFACTURER KNOWN FOR PRODUCING TOP NOTCH PRODUCTS & BEST SERVICE RECOGNITION AMONGST CUSTOMERS. A point of utmost significance is that you'll need to select a company which nails your specific requirement. This may be they can design to order, have quick prototype or appropriate lot size for prototyping. A good partner in your project can make a difference

Some parts are harder to machine than others. Sometimes you might need a strange size, unique touch points or materials that tie into your ace design work. That is creativity, and innovation terrain. Well, then say what you like, however When one of the Hardest Challenging to machine in CNC machining a manufacturer will always find all kind way when Wow have right tools and skills & ideas. An intelligent manufacturer will have the capabilities to think out-of-the-box, so if you partner with a good one they should be able to manufacture whatever product it is that requires fabrication (assuming necessary process design/simulations first took prior).

Our supply chain integrated seamlessly cnc machining parts manufacturer everything from basic material procurement to advanced processes such as electroplating surface treatment and titanium alloy oxidation This broad approach coupled with a strict quality control system ensures that each stage is in line with the highest standards providing consistently efficient and top-quality products and services that dramatically improve customer satisfaction and strengthen our reputation as a reliable supplier

We have a cnc machining parts manufacturer quality control system that's accredited with ISO 9001 ISO 13485 ISO 14001 AS9100D and IATF 16949 The system also comes with the latest tools for inspection as well as a professional team of quality inspectors From inspection of raw materials to the final delivery our quality control process ensures that each product meets or exceeds the international standards To improve our quality control standard we constantly improve our the production process We regularly train our employees on quality control

Yuyao Phelp Electric Appliance Co., Ltd., one of China's top three citrus juicer exporters is cnc machining parts manufacturer the industry in terms of design innovation as well as service quality. We are always striving to improve our blender and juicer products, continuously researching and developing more novel designs, and more durable products that meet the demands of all customers.

our product line covers various precision parts for the automotive industry as well as cnc machining parts manufacturer and medical equipment such as high-precision components for heart stents and durable and reliable parts for industrial machinery we're dedicated to meeting the needs of these industries for quality performance and innovation ensuring the quality of each item meets the most stringent standards with top quality and technological advancement we meet our customers' personalized needs

Copyright © Huizhou Jiyan Hardware Co., Ltd. Alle rettigheter reservert | Personvernerklæring