Materials: Metals, plastics, and composites

Advanced Machinery: 3 to 6-axis CNC machines

Surface Finish: Ra 0.1 to 3.2

Tight Tolerance: Standard at ±0.05mm; critical areas down to ±0.001mm

| • PRODUCT DESCRIPTION |

| material |

1. Stainless Steel: SS303, SS304, SS316, SUS420J2, etc 2. Steel: 12L14, 12L15, C45(AISI1045), etc 3. Carbon Steel: CH1T, ML08AL, 1010, 1035, 1045, etc 4. Alloy Steel: 10B21, 35ACR,40ACR, 40Cr, 35CrMn, etc 5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc 6. Brass: C3604, C38000, etc |

| Grade | 4.8, 8.8, 10.9, 12.9. |

| Surface Treatment |

Zinc plated, Nickel plated, Chrome plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating and Electrophoresis, etc |

| Standard | ISO, DIN, ANSI, JIS, BS and Non-standard. |

| Certificate |

GB/T19001-2008/ISO9001:2008 It can match ROHS,SGS and environment protection |

| Products Range | Dia: 2-200mm or as your request |

| Manufacture Process | Raw Material/QC/Heading/Thread/HeatTreatment/Surface Treatment/QC Inspection/Sorting and Packing/Shipping |

| Tolerance |

+/-0.005mm or as your request |

| Sample Service | Samples for standard fasteners are all in free |

| Lead Time | 15-20 days after order confirmed or as your request |

| Carton Size | 270*220*120mm or customized |

| After-sales Service | We will follow up every customer and solve all your problems satisfied after sale |

| • PRODUCT PICTURES |

| • MORE PRODUCTS |

| • WHY CHOOSE US ? |

|

WHY US ?

1. We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision turning parts, CNC precision milling parts, automatic lathe parts, EDM wire cutting parts etc for over 10 years.

2. With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

3. We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

4. Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.005mm.

5. Factory direct price and on time delivery.

6. Small quantity acceptable.

7. Free samples available.

8. OEM workable. |

PRODUCTION CAPABILITIES

| Manual | Turning | Milling |

| Gringding | Prototyping | Drilling |

| Broaching | Automic | CNC Milling |

| CNC multi axis | CNC lathe turning | Production milling |

| Production turning | Prototyping | Thread milling work |

| CNC Production turning | CNC prototyping | Production gear manufacturing |

TECHNIC SERIES

| CNC machining | Laser Cutting | Turning |

| Grinding | Milling | Hobing |

| Casting(Sand/die casting) | Stamping | Welding |

| Bending | EDM | Wire Cutting |

| Laser engraving | Knurled | Etc... |

| • WORKSHOP |

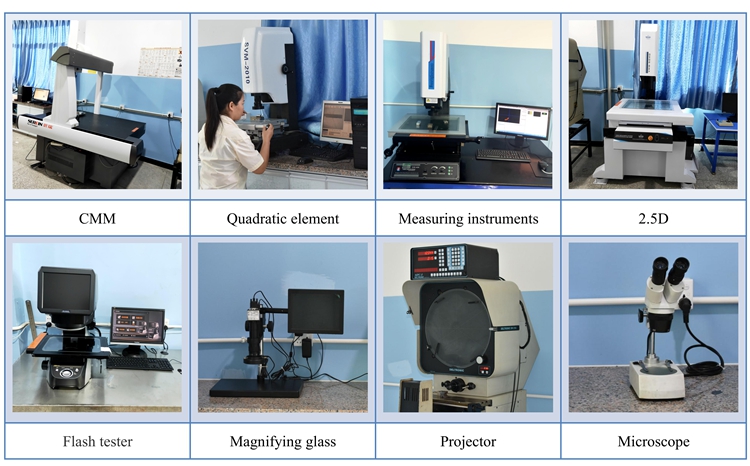

| • INSPECTION EQUIPMENT |

Our QC department will inspect the products in production and after production.

We promise you as below:

1. Check the raw material before the production.

2. Have random inspection during the production.

3. Make 100% inspection before the shipment.

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 10 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Huizhou city and you can get more detailed information by browsing our website: www.hzjiyan.com.cn

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your order quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

5.How to get an accurate quotation?

A: If you are interested in our products, please provide us with below information:

♦ Drawings, photos or samples of products.

♦ Detailed sizes of products.

♦ Material of products.

♦ Surface treatment of products.

♦ Ordinary purchasing quantity.

Jiyan

Introducing the Carbon steel spur gear roller shaft cold mill roll high grade steel shaft from a game-changing product in the industry. The product is carefully crafted and made of premium quality materials, ensuring maximum durability and longevity. It is the perfect fit for all your industrial needs and guarantees a high level of performance, efficiency, and reliability.

Created to meet all of your requirements and exceeds your expectations. Consists of top-notch jiyan high-grade steel, which means that it can withstand the wear and tear of daily uses is commercial. It is a fantastic fit for heavy-duty applications, and you may count on it to supply the quality results being greatest.

Versatile and can be used in many different applications. In the constructions sectors, the productions industry, or any other that calls for top-quality equipment, Jiyan's Carbon steel spur gear roller shaft cold mill roll high-grade steel shaft is an ideal solution for you whether you're looking to uses it.

Designed to be easy to make use of. It is rather user-friendly, which means that you don't need any special skills expertise to runs it. All you need to do is follow the instructions provided, and you shall manage to uses it with ease.

Competitively priced. Affordable and will be offering excellent value for your money. It is an investment is great you will maybe not be sorry for making. You will have the ability to spends less in the run is long avoiding costly repairs and replacements that may arise from using inferior items.

Why not give Jiyan's Carbon steel spur gear roller shaft cold mill roll high-grade steel shaft a try today and experience the difference for yourselves.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy