Materials: Metals, plastics, and composites

Advanced Machinery: 3 to 6-axis CNC machines

Surface Finish: Ra 0.1 to 3.2

Tight Tolerance: Standard at ±0.05mm; critical areas down to ±0.001mm

| • PRODUCT DESCRIPTION |

Material |

1. Stainless Steel: SS303, SS304, SS316, SUS420J2, etc 2. Steel: 12L14, 12L15, C45(AISI1045), etc 3. Carbon Steel: CH1T, ML08AL, 1010, 1035, 1045, etc 4. Alloy Steel: 10B21, 35ACR,40ACR, 40Cr, 35CrMn, etc 5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc 6. Brass: C3604, C38000, etc |

Grade |

4.8, 8.8, 10.9, 12.9. |

Surface Treatment |

Zinc plated, Nickel plated, Chrome plated, Passivation, Oxidation, Anodization, |

Standard |

ISO, DIN, ANSI, JIS, BS and Non-standard. |

Certificate |

GB/T19001-2008/ISO9001:2008 It can match ROHS,SGS and environment protection |

Products Range |

Dia: 2-200mm or as your request |

Manufacture Process |

Raw Material/QC/Heading/Thread/HeatTreatment/Surface Treatment/QC Inspection/Sorting and Packing/Shipping |

Tolerance |

+/-0.005mm or as your request |

Sample Service |

Samples for standard fasteners are all in free |

Lead Time |

15-20 days after order confirmed or as your request |

Carton Size |

270*220*120mm or customized |

After-sales Service |

We will follow up every customer and solve all your problems satisfied after sale |

| • PRODUCT PICTURES |

| • MORE PRODUCTS |

| • WHY CHOOSE US ? |

|

WHY US ?

1. We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision turning parts, CNC precision milling parts, automatic lathe parts, EDM wire cutting parts etc for over 10 years.

2. With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

3. We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

4. Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.005mm.

5. Factory direct price and on time delivery.

6. Small quantity acceptable.

7. Free samples available.

8. OEM workable.

|

PRODUCTION CAPABILITIES

| Manual | Turning | Milling |

| Gringding | Prototyping | Drilling |

| Broaching | Automic | CNC Milling |

| CNC multi axis | CNC lathe turning | Production milling |

| Production turning | Prototyping | Thread milling work |

| CNC Production turning | CNC prototyping | Production gear manufacturing |

TECHNIC SERIES

| CNC machining | Laser Cutting | Turning |

| Grinding | Milling | Hobing |

| Casting(Sand/die casting) | Stamping | Welding |

| Bending | EDM | Wire Cutting |

| Laser engraving | Knurled | Etc... |

| • WORKSHOP |

| • PRODUCTION PROCESS |

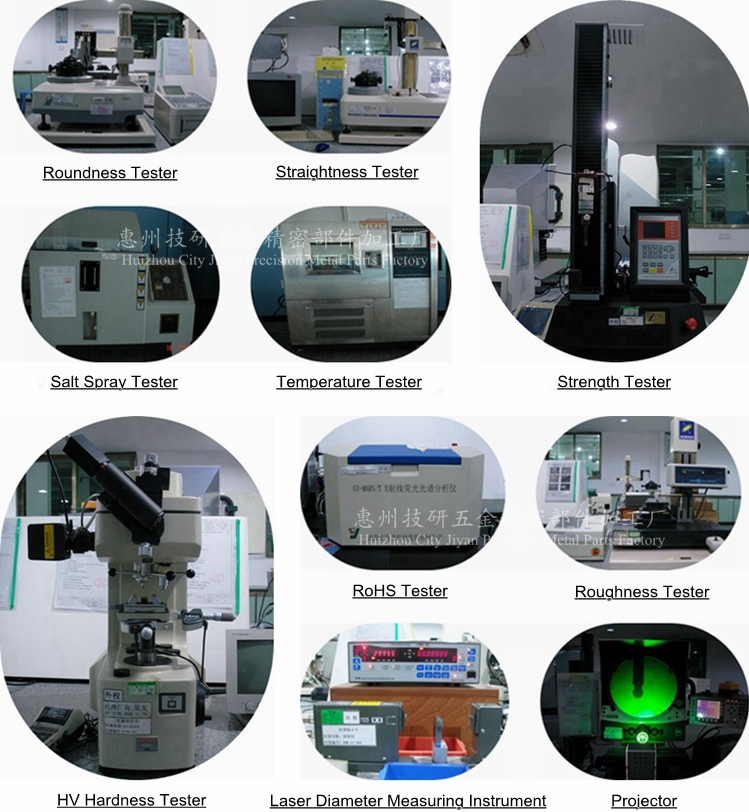

| • INSPECTION EQUIPMENT |

Our QC department will inspect the products in production and after production.

We promise you as below:

1. Check the raw material before the production.

2. Have random inspection during the production.

3. Make 100% inspection before the shipment.

| • PACKAGING |

| • SHIPPING |

|

Delivery: 1) Less than 50kg, you could choose express, such as DHL, UPS, FedEx, TNT and EMS. (door to door,so convenient)

2) From 50kg to 200kg, you could choose to send by air. (fast and safe, but expensive)

3) More than 200kg, you may consider to send by sea. (cheapest, but long transit time)

4) We can also deliver as client’s requirment

5) Nearest Port: Shenzhen Port

6) We will choose the cheapest and safest way to ship the goods to you. |

|

| • F A Q |

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 10 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Huizhou city and you can get more detailed information by browsing our website: www.hzjiyan.com.cn

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your order quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

5.How to get an accurate quotation?

♦ Drawings, photos or samples of products.

♦ Detailed sizes of products.

♦ Material of products.

♦ Surface treatment of products.

♦ Ordinary purchasing quantity.

JIYAN

The Precision Lathe Parts CNC Turning Work Stainless Steel CNC Processing is a top-quality products that offers precision and durability. This products is perfect for those who requires high-quality metal parts that can withstand the rigors of daily used. With years of experiences and expertise in manufacturing high-quality CNC machine parts, Jiyan ensures that each parts is made with precision and care.

Produced with high-grade steels is stainless ensuring maximum strength and resilience. Jiyan uses the most recent CNC machining technology to achieves superior accuracy and precision in every components, making certain each pieces is regarding the highest quality is possible. Additionally, these right parts are designed to meet with the unique requirements regarding the customers, ensuring they have been delivered exactly to your specifications.

CNC turning is just a process that makes used of machines being computer-controlled creates metal parts. The process involves spinning the metals and then using an instrument is cutting shapes it into the required type. With Jiyan’s state-of-the-art technology, the turning process is completed because of the precision is greatest, ensuring the product’s high-quality.

Ideal for a range is wide of. These parts may be used in various applications, making them highly versatile from automotive to aerospace. Customers can count on Jiyan to deliver parts tailored to their demands which are specific.

Takes pride in its ability to quickly work effortlessly and. With years of expertise and expertise on the market, they are committed to delivering the quality products which can be highest with exceptional service. Their focus on dedication and detail to quality has earned them the trust of customers worldwide.

The Jiyan Precision Lathe Parts CNC Turning Work Stainless Steel CNC Processing is a top-quality product that offers unmatched precision and durability. Whether you're in the automotive, aerospace or any other industry, you can count on Jiyan to deliver the best quality CNC machined parts that meet your specific requirements. With their commitment to excellence and exceptional service, Jiyan is the perfect choice for those seeking the highest quality products.

Copyright © Huizhou Jiyan Hardware Co.,Ltd All Rights Reserved | Privacy Policy