CNC обробка використовується для виготовлення деталей для машин і майже всього іншого на Землі з великою точністю. Написана на комп'ютерній програмі, яка керує машиною для швидкого і точного виготовлення деталей. Як правило, цей процес призводить до мінімального відходу, і всі деталі виготовляються абсолютно ідентичними кожного разу, що важливо для якості.

Існує багато різних металів, з якими може працювати CNC-обробка, наприклад, сталь, алюміній, мідь тощо. Ця універсальність означає, що її можна використовувати для виготовлення різноманітних виробів — від деталей літаків, які мають бути надзвичайно міцними і ультра легкими, наприклад, формування панелі приладної дошки на деяких літаках… …до нежних компонентів для музичних інструментів, яким потрібна докладна праця гранами.

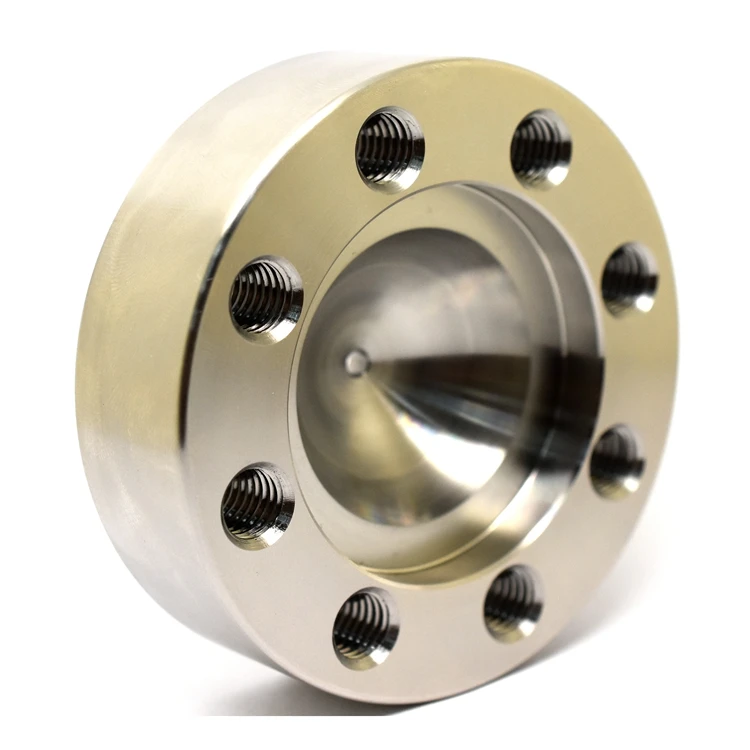

Також це добра річ, що обробка ЧПУ може забезпечувати складні та скрупульовані деталі. Оскільки машина керується комп'ютерною програмою, вона може розрізати та формувати метал у надзвичайно точний спосіб - процеси, які могли б бути дуже важкими або навіть неможливими для людини, щоб виконувати їх вручну. Здатність виробляти складні форми є ключовою для виготовлення унікальних продуктів.

Допуски — це термін, який часто згадується при обговоренні обробки ЧПУ, і він пов'язаний з точністю, яку досягається за допомогою цього методу. Допуски — це дозволені межі розмірів, які встановлюються інженерами-конструкторами. Це може призвести до того, що деталь не буде працювати правильно всередині машини, для якої вона призначена. Якщо ми зробимо допуски занадто суворими, це також може означати, що вартість виробництва зросте через необхідність більшої уваги під час виробництва.

Таємницею виготовлення складних деталей з металу є співробітництво між станком та Комп'ютерною Програмою. Він (станок) має різні види інструментів для розрізання та формування металу по-різному. Ця комп'ютерна програма є важливою, оскільки вона фактично навчає станок, що робити, і як всі ці інструменти переміщуються, прикріплені.

Це вимагає дуже складної комп'ютерної програми для проектування складної деталі. Вона розділяє деталь на серію менших, більш досяжних компонентів і керує станком для правильного будівництва кожного шматка. Крім того, у разі, якщо під час процесу все не йшло добре, програма може вносити деякі зміни в реальному часі для виправлення проблем.

3D друкування — захоплива гілка для майбутнього CNC обробки. Концепція виготовлення деталей шароматуванням матеріалу відкрила цілу сферу, яка ніколи не була можливою з традиційними методами виробництва. Технологія 3D друку вже застосовується в деяких галузях, але їй ще далеко до досягнення вищого рівня переносності.

Наша ланцюжок постачання безперебійно керує CNC обробкою металевих деталей від найпростішого забезпечення матеріалами до складних процесів, таких як електрохромування поверхонь і оксидування титанової сплаву. Комплексний підхід і суворий контроль якості забезпечують те, що кожен процес відповідає найвищим стандартам. Результат - ефективні, стабільно високоякісні, надійні продукти та послуги, які підвищують задоволеність наших клієнтів.

наш асортимент продукції включає широкий вибір точних деталей для автотранспортної промисловості, космічної промисловості, медичного обладнання, включаючи найкращі компоненти для серцевих стентів, а також міцні та надійні компоненти для промислового обладнання. Нашою метою є задовolenня вимог цих галузей у термінах якості матеріалу, точності та інновацій. Ми гарантуємо, що всі продукти відповідають найвищим стандартам обробки металевих деталей методом CNC. Ми задовольняємо потреби наших клієнтів за допомогою високої якості та сучасних технологій.

Yuyao Phelp Electric Appliance Co., Ltd., одна з трьох найбільших експортерів цитрусових соковиць в Китаї, постійно проводить дослідження та експериментує з інноваційними дизайнерськими розробками, щоб забезпечити найвищу якість своїх соковиць та блендерів, які відповідають вимогам наших клієнтів.

Щодо якості наших продуктів, ми створили повну систему управління, сертифіковану за стандартами ISO 9001, ISO 13485, ISO 14001, AS9100D, а також виробництво металевих деталей методом CNC обробки. Ми оснащені найсучаснішим обладнанням для перевірок та професійною командою контрольного управління якістю. Від початкової перевірки сировини до етапу доставки, наш процес контролю якості забезпечує, що кожен продукт відповідає чи перевищує міжнародні стандарти. Неперервно покращуємо виробничий процес та регулярно навчаємо наших працівників управління якістю для підвищення стандартів управління якістю.

Авторське право © Huizhou Jiyan Hardware Co.,Ltd. Всі права захищені | Політика конфіденційності